← back

Silicone-

lamination

Present your picture with a sense of depth behind plexiglass.

Silicone lamination is a technique, whereby a sheet of acrylic is bonded to the front of a photograph with liquid silicone. The backpanel protects and stabilizes the photograph.

For the production you should plan at least one week, since the bonding needs several days to set and the picture can only be cut after that. Aluminum rails in a variety of sizes can be affixed to the back panel as hangers. Minor scratches can later be polished away with acrylic polishing paste. The acrylic is available in 2, 3 and 4 mm thickness.

Suitable types of paper

Inkjet prints: simple, matte papers will work. Semi-matte and glossy inkjet papers can not be processed with silicone lamination due to their texture. We recommend the following inkjet papers:

- Epson Enhanced Matte, Epson Enh. Archival Matte

- Tecco Matte, Tecco Matte

Digital exposure on photo paper: All simple photo papers can be processed as silicone lamination. It is recommended to use matte photo paper, since glossy photo paper can be perceived as an additional reflective surface behind the acrylic panel. We recommend matte paper. Analog magnification: We recommend matte paper.

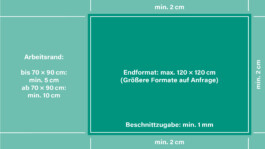

Margin

We need a specific margin in order to guarantee a proper processing of the silicone lamination. An additional 5 cm margin has to be added to one of the print’s shorter sides. For larger photographs, (from 70 × 90 cm) the added margin should at least be 10 cm on the shorter side. The other three sides need a margin of at least 2 cm.

Trimming

The trimming edge of a silicone lamination will be approximately 1 mm.

Maximum paper size

Up to a size of 120 × 120 cm, silicone laminations can be easily processed. For larger formats, there is a risk that the rear plate can detach due to fluctuations in temperature and himidity. For a permanent presentation a framing is essential. You may contact us for more information.

Back panel

For smaller prints up to 70 × 90 cm you can choose between 2 or 3 mm Dibond® panel, and clear or white acrylic backing. For larger sizes, an acrylic back panel does not provide sufficient stability. In this instance, we would recommend a Dibond® back panel with a full hanging rail.

Processing time

Since the silicone lamination technique requires preparations and drying time of several days, we estimate fourteen business days for the processing of silicone laminations. The processing time will be longer for larger orders.

Hanging Cleats

Aluminum cleats will be fixed to silicone laminations with a Dibond® back panel. Acrylic cleats will be fixed to silicone laminations with an acrylic back panel. If the print is larger than 70 × 90 cm, we recommend a full, set of aluminium cleats be affixed to the back plate. Silicone laminations in these sizes will flex quite a bit due to the material’s properties. and will need the additional stability provided by the cleats. It should be kept in mind that an acrylic back panel changes over time (for example, through expansion caused by humidity and temperature fluctuations).

Longevity

Our tests have shown that inkjet prints last longer than photos developed with chemical exposures. The light resistance is further increased by Lamination behind acrylic. You can have a look at the tests upon request.

Surface treatment

The acrylic surface can be cleaned with a special cleansing agent. Minor scratches can be polished away with a polishing agent. Deeper scratches can be sanded down, although this treatment will always leave slight marks. Matte acrylic surfaces cannot be restored. Other forms of surface treatments can lead to scratches. Cleaning fluids, especially window cleaners, can affect the acrylic glass. The special cleansing and polish agent suggested can be obtained from us.

Acrylic to Acrylic/Film

Silikone can not set between two panels. A silicone lamination of acrylic to acrylic or acrylic to film cannot be realized because Silicone needs oxygen to dry and set. Silicone cannot set between two panels.

↑ to the top

|

|

|

|

← back

Silicone-

lamination

Present your picture with a sense of depth behind plexiglass.

Silicone lamination is a technique, whereby a sheet of acrylic is bonded to the front of a photograph with liquid silicone. The backpanel protects and stabilizes the photograph.

For the production you should plan at least one week, since the bonding needs several days to set and the picture can only be cut after that. Aluminum rails in a variety of sizes can be affixed to the back panel as hangers. Minor scratches can later be polished away with acrylic polishing paste. The acrylic is available in 2, 3 and 4 mm thickness.

Suitable types of paper

Inkjet prints: simple, matte papers will work. Semi-matte and glossy inkjet papers can not be processed with silicone lamination due to their texture. We recommend the following inkjet papers:

- Epson Enhanced Matte, Epson Enh. Archival Matte

- Tecco Matte, Tecco Matte

Digital exposure on photo paper: All simple photo papers can be processed as silicone lamination. It is recommended to use matte photo paper, since glossy photo paper can be perceived as an additional reflective surface behind the acrylic panel. We recommend matte paper. Analog magnification: We recommend matte paper.

Margin

We need a specific margin in order to guarantee a proper processing of the silicone lamination. An additional 5 cm margin has to be added to one of the print’s shorter sides. For larger photographs, (from 70 × 90 cm) the added margin should at least be 10 cm on the shorter side. The other three sides need a margin of at least 2 cm.

Trimming

The trimming edge of a silicone lamination will be approximately 1 mm.

Maximum paper size

Up to a size of 120 × 120 cm, silicone laminations can be easily processed. For larger formats, there is a risk that the rear plate can detach due to fluctuations in temperature and himidity. For a permanent presentation a framing is essential. You may contact us for more information.

Back panel

For smaller prints up to 70 × 90 cm you can choose between 2 or 3 mm Dibond® panel, and clear or white acrylic backing. For larger sizes, an acrylic back panel does not provide sufficient stability. In this instance, we would recommend a Dibond® back panel with a full hanging rail.

Processing time

Since the silicone lamination technique requires preparations and drying time of several days, we estimate fourteen business days for the processing of silicone laminations. The processing time will be longer for larger orders.

Hanging Cleats

Aluminum cleats will be fixed to silicone laminations with a Dibond® back panel. Acrylic cleats will be fixed to silicone laminations with an acrylic back panel. If the print is larger than 70 × 90 cm, we recommend a full, set of aluminium cleats be affixed to the back plate. Silicone laminations in these sizes will flex quite a bit due to the material’s properties. and will need the additional stability provided by the cleats. It should be kept in mind that an acrylic back panel changes over time (for example, through expansion caused by humidity and temperature fluctuations).

Longevity

Our tests have shown that inkjet prints last longer than photos developed with chemical exposures. The light resistance is further increased by Lamination behind acrylic. You can have a look at the tests upon request.

Surface treatment

The acrylic surface can be cleaned with a special cleansing agent. Minor scratches can be polished away with a polishing agent. Deeper scratches can be sanded down, although this treatment will always leave slight marks. Matte acrylic surfaces cannot be restored. Other forms of surface treatments can lead to scratches. Cleaning fluids, especially window cleaners, can affect the acrylic glass. The special cleansing and polish agent suggested can be obtained from us.

Acrylic to Acrylic/Film

Silikone can not set between two panels. A silicone lamination of acrylic to acrylic or acrylic to film cannot be realized because Silicone needs oxygen to dry and set. Silicone cannot set between two panels.

↑ to the top

|

|

|

|

↑ to the top |

↑ to the top |